Introduction

The world is increasingly turning its attention to the pressing issue of plastic pollution. With millions of tons of plastic waste generated annually, the need for sustainable alternatives is urgent. One promising solution lies within the realms of biotechnology and artificial intelligence: synthesizing biodegradable plastics from algae. This article delves into how AI robotic labs are revolutionizing this process, enabling large-scale production of eco-friendly materials that could mitigate environmental damage.

The Science Behind Biodegradable Plastics

Biodegradable plastics are designed to break down into natural substances when exposed to the environment. Unlike traditional plastics, which can take centuries to decompose, biodegradable options can disintegrate in a matter of months or years. The primary components in many biodegradable plastics are starches, polylactic acid (PLA), and, increasingly, algae.

Why Algae?

Algae present a unique opportunity for biodegradable plastic production due to their rapid growth rates and high biomass yield. Here are several reasons why algae are becoming the preferred source:

- Fast Growth: Algae can double their biomass in just a few hours in optimal conditions.

- Minimal Resources: They require less water and land compared to traditional crops.

- Carbon Sequestration: Algae absorb CO2, making the production process more sustainable.

The Role of AI and Robotics

AI and robotics are at the forefront of this innovative approach. Robotic labs equipped with AI capabilities can optimize the entire process of synthesizing biodegradable plastics. Here’s how:

1. Streamlined Research and Development

AI algorithms can analyze vast datasets to identify the most efficient strains of algae for plastic synthesis. Machine learning models predict which genetic modifications would yield the best results, accelerating the R&D phase dramatically.

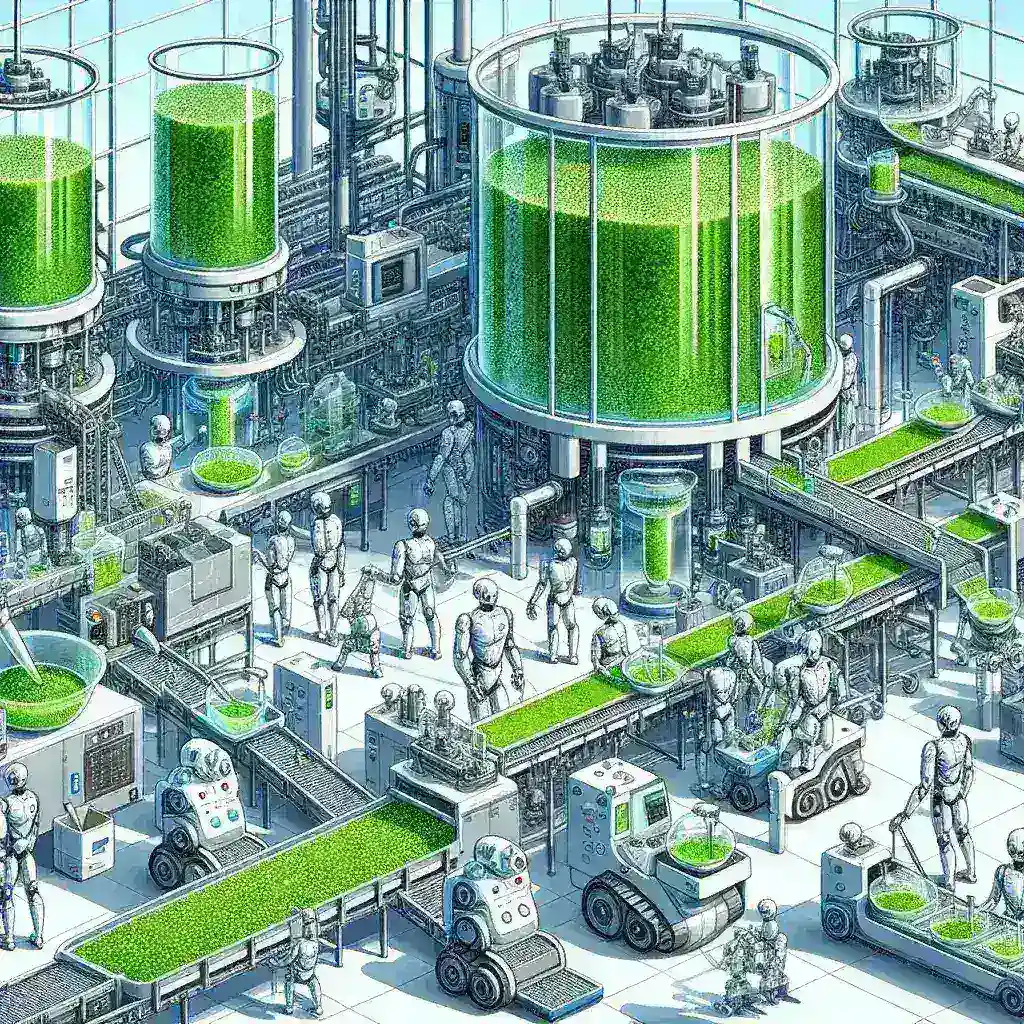

2. Automated Cultivation

Robotic systems can manage the cultivation of algae in controlled environments, ensuring optimal conditions for growth. This automation helps maintain consistent quality and maximizes yield, crucial for large-scale production.

3. Real-time Monitoring and Adjustments

Equipped with sensors, robotic labs can monitor environmental variables such as light, temperature, and nutrient levels. AI can analyze this data in real-time, making adjustments to improve growth rates and product quality.

Current Progress and Case Studies

Several organizations have begun to implement AI-driven robotic labs to synthesize biodegradable plastics from algae. Here are some notable examples:

Case Study 1: Algenesis Materials

Algenesis has developed a method of converting algae oils into a polymer that can replace petroleum-based plastics. Their AI-enabled lab has achieved significant advancements in optimizing the polymerization process, making the materials not only biodegradable but also durable.

Case Study 2: PhycoRenewables

PhycoRenewables focuses on cultivating algae in large bioreactors. By utilizing AI for process optimization, they have successfully scaled up production, providing sustainable materials for various industries, including packaging and textiles.

Advantages of Using AI Robotic Labs for Bioplastics

The integration of AI and robotics into the production of biodegradable plastics offers numerous advantages:

- Efficiency: Automated systems reduce labor costs and increase production speed.

- Quality Control: AI ensures consistent product quality by monitoring growth conditions and adjusting parameters accordingly.

- Environmental Impact: This method reduces reliance on fossil fuels and minimizes plastic waste in landfills and oceans.

Challenges and Considerations

Despite the promising advancements, several challenges remain in deploying AI robotic labs for synthesizing biodegradable plastics:

1. Technology Costs

Initial investments in robotic systems and AI technology can be substantial, potentially limiting access for smaller companies.

2. Scaling Production

While laboratory successes are promising, scaling production to meet global demand poses logistical and technical challenges.

3. Regulatory Hurdles

As with any emerging technology, regulatory frameworks must evolve to ensure safety and sustainability in production processes.

The Future of Biodegradable Plastics from Algae

As technology progresses, the future of biodegradable plastics synthesized from algae looks promising. Predictions indicate that as more companies adopt AI and robotic systems, production costs will decrease, making these sustainable materials more accessible on a global scale. Furthermore, public awareness of environmental issues will likely amplify demand for biodegradable options, incentivizing further innovation.

Conclusion

AI robotic labs synthesizing biodegradable plastics from algae represent a groundbreaking intersection of technology and sustainability. By harnessing the rapid growth of algae and the efficiency of AI, we can take significant strides towards reducing plastic waste and promoting environmental health. As this technology matures, it has the potential to redefine the materials we use in our daily lives, paving the way for a more sustainable future.